Question VI motor bike

Hello

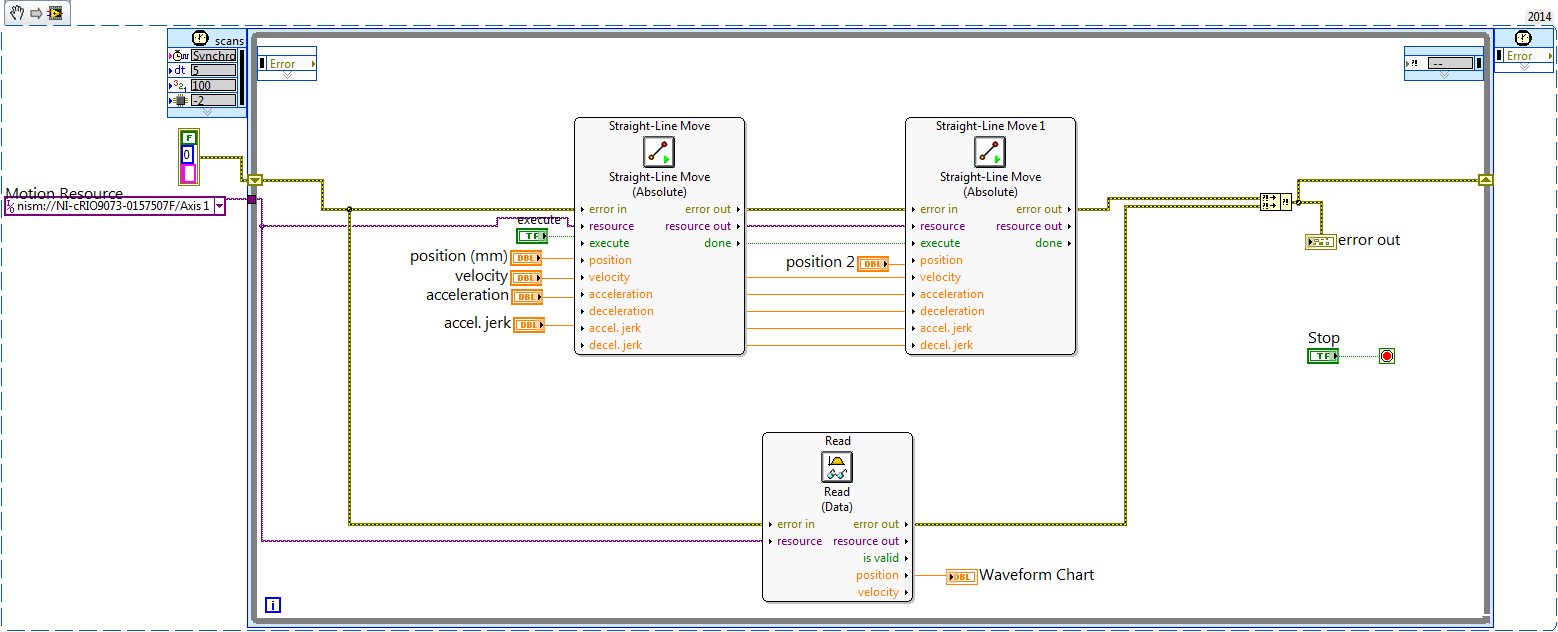

I'm writing a VI that performs a cycle continuously a stepper motor that is connected to a linear actuator. I wish I could order to move the linear actuator of 2 inches, retract 0 thumb and loop this profile so that she could continue to move without user interaction (aka. not having not to have someone click the button to run the profile each time he completed these movements.) I found how to program to move the desired length but it will not continually loop through the code is placed in a timed loop. This is a .png of the block schema file (I've also attached it):

I use 2014 LabVIEW SoftMotion Module real-time module with a cRIO-9073 chassis. I have exhausted all my ideas; Therefore, any help on how to loop or repeat continuously this profile would be greatly appreciated. Thank you!

Function blocks can be difficult to make it work properly. I recommend looking at property SoftMotion/systematically examples of node instead of using function blocks. I think that there is a state machine example you should be able to easily change at your convenience.

The entry "run" on function blocks is sensitive edge up. So what happens when the user clicks on the "run" command, the first block of function will begin. When the engine is complete that move, she will assert that Boolean "done" and this value will cause the second function block to execute (because he sees a rising edge on its entry 'running'). What you want is when the second function blocks finishes, you get a rising edge on the entry "run" of the first block function so that it starts again. You should be able to do with a shift register and Boolean logic.

Thank you

Tags: NI Software

Similar Questions

-

Can I connect a Bluetooth monitor and bike cadence monitor simultaneously for 5 s iPhone

Can I connect a Bluetooth monitor and bike cadence monitor simultaneously for 5 s (iOS 9.2) iPhone?

Hi thepaulbarlow,

Welcome to the communities of Apple Support! I'm sure we can help you with your question. In general, the iPhone should be capable of supporting multiple Bluetooth devices, as described in the following article:

If you have any questions for matching one or the other device, you can find information and the steps in the following article useful:

See you soon

-

The bike 360 Gen 2 charger will work in Australia?

The bike 360 Gen 2 is not yet released in Australia but I would buy one and shipped it to the Australia.

Does anyone know if there will be problems with the loader works in Australia? I guess I would need to get the adapter to allow me to plug into an Australian power but it would be my only question?

Unless of course someone knows the release date of the Gen 2 in Australia and it is really close. Then maybe I could wait!

Thank you very much

The Australia standard supply voltage is 230V 50 Hz. us. and Canada use 100/120V 50/60 Hz. The power adapter supplied with the bike 360 Gen 2 will use 100-240 v at 50 / 60 Hz. You only need one to two U.S. pins on Australian adapters to make things work. Adapters are available on the internet for less than US $5.00.

I hope this helps!

-

Just a quick question - I ordered a bike 360 the day he got out when it was available.

The order page says shipping day 2 with a delivery 9. However, it has not yet shipped, nor have I learned anything by saying that it was the out of stock or out of stock. It will still be there by the 9th?

Also for anyone who ordered Motorola - has your watch still shipped

-Ryan

I check - what is the order number? I'll PM you.

-

Bike Turbo G: home button and right does not, without quick settings and issues more

My bike Turbo G suddenly crashed last night, while I was working with Photos of Google. The phone is about 1 month, purchased from Flipkart. Here are the questions that have emerged all of a sudden:

- No function button Home and the right button. They do not work.

- No quick drop-down settings menu. All of a sudden is not working.

- Cannot transfer from phone to computer I choose is no longer the option to transfer files. (no menu drop-down)

- No notification.

- Camera twist-gesture does not.

- Flashlight chopping gesture does not.

- No lock screen.

- Option not available factory reset. Reset the phone option is grayed out.

Tried Recovery Mode (power + flight to the down button, then flight Power + up button) but the problems are still there.

While Googling found that other users have had the same problems.

What is the solution? Help, please!

This happens when the system: OS crashes. U go to Recovery Mode and then choose Wipe Cache partition and after wiping Cache Partition, choose the device to reboot.

Wipe Cache partition will delete your personal files or anything like that. Erase all dump and error and cache generated by the Android operating system.

I hope that it is surely help you.

-

Dear friends,

My bike E restarts frequently. It is having this problem since last (I think after update of KitKat v4.4.4). Sometimes it restarts more than five times in an hour. More often it is restarted when I get the screen locking pin (previously it was boss - then I also had the same problems). Sometimes when I press the screen lock button it will show the power / option aircraft and in the two seconds it will restart (no matter if select back button) or the option available. But it's not to restart everytime I press the power button. I read the posts earlier on the same issue and I removed the uninstalled software cleanmaster I've had, but still I have the problem, I disruption in case of emergency, because it takes more than 60 seconds to restart.

In the meantime a solution

Hello, can you pleasepost on this thread, so that we can all this in one place. Note that there are Matt, our Forums Manager, has posted some questions and measures to be taken to help understand what is happening.

In the future, please use search to find the discussions already on your topic, compared to open a new one. Thank you!

Locking thread.

-

Bike E 1 St Assist App does not work

Bike E bike assist integrated app does not work, how to use proprly?

I guess we play 20 questions then? Unless you can explain your problem, it will be difficult to provide assistance. What have you tried so far?

Are you using any headset or do you want the speaker to read the text message?

Do you have a House somewhere?

You are in the original position when you test?

Location services value precision?

Is there any bike Assist icon to indicate that you are in a place of welcome?

Please try to answer with multiple sentences to explain your problem and what you have tried. I asked you to do it before. We cannot help you if you don't help us.

-

Engine for MyRio adapter command 2 DC motors

Hello

I have a question about the adapter engine for the MyRio. I found the following code example:

https://decibel.NI.com/content/docs/doc-45592

This afternoon, I was able to drive a motor continuous using this VI, but I want to use to control 2 Motors continuous. I tried the following (see photo) and it did not work.

What should I do for the second DC motor?

Thank you!

Hello

Well, the next time you post, it would be useful to have all the information to start with (what does your system, errors, measures

you have taken to solve the problem, etc.). This way more people will respond and we can help you more easily.

By parallel loops, I just run two processes in separate loops at the same time in the same VI (what they do on the link).

If you think about it logically if this initial process is running one engine, then do the same exact process but that it points to the

second motor will run the second engine. So, if you include the two pieces of code (exactly the same but different engines references) in the same VI then it can run two engines.

If you look at the link I have attached before she speaks of two ongoing processes at the same time within the same VI.

You can then use queues and the authors of the notifications (look in them) to communicate between the two processes you use, allows from Control Panel even before to control them and stop them both at the same time.

With this, you should be able to all both enforce.

Hope this helps

-

Use of the bike to connect Chrome Extension/RAM

Hello

I have 2 questions. The first concerns the extension of the Moto connect Chrome. The application on my 1st gen x bike allowed me to receive and send TEXT messages from my laptop or a chromebook through the extension to chrome. When I open the app on my new edition Pure, there is no option for me to add the chrome extension. I even tried to extract my 1 x apk file and install it on my EP with no luck. I use version is 2.06.16 - pc-249. This is the version most up-to-date according to the store to play as well. I really like this feature of my x 1 and would like to know how to operate on my PE.

Another question, I'll have, it's that the EP seems to use a lot of RAM to the system. The system uses up about 1 GB of RAM after a fresh reboot. It seems extremely high, is almost three times what my Nexus 7 Tablet and my x 1 bike use, 5.1.1 and 5.1, respectively. What could this go? Or is it quite normal for phones equipped with 64-bit processors use a ton of RAM to the system?

Thank you!

Andy

-

Control of Stepper Motor with case NI USB-6009

Hi all

I am currently creating a movement control system with a double movement actuator

and two bipolar chopper drives (see table), which should power the motor. We already have a NI USB 6009 in our lab, so I was wondering if I could use it to send signals to the two pilots to control the speed and direction of each axis on the engine?

Enclosed driver's manual indicates that input signals should be 0-5 V DC (TTL logic). I have been informed by the engine distributor that the 0-5 V DC TTL drivers required, the signals are analog. The NI USB-6009 manual reading, there are two 0-5 V analog outputs on the acquisition of data usb so I could provide two signals?

There are often posted however similar problems, it is usually a digital signal NI6009/6009 sends the driver. Looking at the driver's manual, can someone tell if an analogue signals or required as I have said, I was misinformed or 0-5 v DC signal will be enough. I can get more in touch with the dealer if you have any questions you guys think I should ask him.

Thanks in advance for any help! It is much appreciated.

I looked in the manual and it doesn't seem to be very clear. I know that the USB-6009 case is capable of AO and DO, then you would be although it is. I could contact the Haydon Kerk support for more concrete details on the gap between what says the manual and what they told you.

-

Bike is hammered on twitter to get answers

So today, I thought that I would check the bike mobility twitter page. Looks like they are themselves hammered by Bionic owners with regard to when we will receive ICS. Response to the questioning on q3 and refers people to the old ICS update page. Last updated 30 July, two other devices have been updated since then. https://forums.Motorola.com/pages/00add97d6c

I think that I like anymore. I came to terms with the fact that the Bionic has been forgotten. Im not going to give the whole "without ever getting a motorcycle again" speech, because I know, I'll do it. Im just going to take this as a learning experience and be more careful next time, I buy another phone.

-

motor action accessed in an unknown part of my code

I've been to this LV thing for quite awhile and I don't think that I was never this confused on something that could very well be a really stupid question on my part. But that's...

I have an AE action engine that I use to store and set target values and read state of a motor controller.

My bug: when my code is running in a State of rest to action "writing engine controller" should not be written on but aims to get in a certain part of the code. I can't seem to find when and where it is written.

Is there a way that I can know exactly when and in what vi specific action in my AE is written? I use a strongly modified producer/consumer model. I have listed all of the appellants of this vi and everything is where it should be. I put a breakpoint on the part "writing engine controller" code and he gets constantly accessible so that my code is idle, but do not because I can only read data from AE when I'm idling.

I am really puzzled.

-

control of DC motor using myDAQ

Hello

I'm building a DC motor using myDAQ command, that I ran into a couple of problem with the STOP button and the Max speed Min. For some reason, the diagram of waveform becomes crazy I will attach my file VI.

Description of the project:

-An engine-engine-OFF button

-A control for fast / slow

-A switch left / right

-A speed once button maximum (100)

-A speed once button minimum (10)

-An indicator of instantaneous speed (0 - stop, maximum 100)

-An indicator that signals the directionCould someone tell me why it happens and how to solve the problem?

Thank you very much!

Best,

Istrael

Hi Istrael,

You use a lot of CPU resources by not including not calendar in your loop. I think that your questions can be resolved if you place a timer 'Until the next ms Multiple' in your 'pulsegenerate.vi' in a loop. This will actually load on your CPU if you set it to 1 ms.

I hope this works,

Paul

-

Need help with LabVIEW code for motor control.

Hello

My name is Sasi. I'm a grad student BME working on my thesis topic of assessment for back pain spine implants. To do this, I'm building a test machine that would apply pure moments of a specimen of the spinal column. I use LabVIEW 8.5 to implement the control of a brushless AC servo motor. My requirement is

Step 1: Initialize the engine.

Step 2: Start moving it to a uniform to the right PLAN (this value of RPM too user can enter).

Step 3: while doing step 2; at the same time read the couple cell data (acquisition of data using Asst.). DAQ o/p is 0 v to 10 V; 0 v is 10 Nm n

10 v is + 10 Nm

Step 4: What torque reached + 10 Nm, i.e. 10 V, the engine stops.

Step 5: from the position where the motor stopped (IE not need to return to the initial position) start moving in the opposite direction to the same

Uniform rpm as in step 2 at the reading of data in the cells of the couple.

Step 6: once more what torque reached-10 Nm, i.e. 0 V, the engine should stop.

Step 7: Repeat "Step 2" to the "step 6' 3 times.

Step 8: Reset engine position.So far, I managed to get the engine to move backward @ a desired vel, the accl, deceleration for 3 cycles before n n. I enclose my code. I have a problem inserting the code for reading DAQmx amidst all this. Can someone help me.

Thnks,

Sasi.

Hi Sonia,.

I took a quick glance to your problem and I think I have a solution for you. I certainly agree with the suggestion of the use of parallel loops Lynn. This will allow the portion DAQmx run uninhibited by the part of the motion, and vice versa. In addition, you need only perform an iteration of the loop of the movement whenever the voltage level exceeds a threshold. Thus, by performing an iteration on the code of movement in the same loop are you iterate over DAQmx code, you essentially waste processor.

I created a VI that should do what you are wanting. I tested it on me and it works very well. You have a tweak a few things to apply to your system (such as motion Council DAQmx and physical channel ID, etc.). I used two parallel loops and event programming. Basically, the loop of movement starts the engine turns at the specified speed. Once the engine is running, he expects the DAQmx loop to tell him that the voltage value has crossed the threshold. When the voltage value exceeds the maximum threshold (I put a value slightly less than 10 to jitter and saturation), the DAQmx loop indicates the loop of the motion that it may end its iteration. The motion loop stops the motion, causes a reversal and repeats the motion. Once the movement has begun, he expects the DAQmx loop once again to tell him that a threshold was held, but this time, it's looking for a minimum threshold. I used "Occurrences" to implement the event programming in LabVIEW.

I've commented the code pretty thoroughly, so I hope that comments will answer all remaining questions. The advantage of using programs that focus on the event for this is that you save time processor, and your movement is more closely synchronized with the DAQmx. Instead of one iteration of the loop of movement as fast as you can, updates every hour, you just put in pause and wait for the other loop to tell you when to start up again. Meanwhile, the processor doesn't have to worry about an iteration of this loop over and over again. In addition, when the accident occurs, you catch him immediately, instead of having to wait until the next iteration. Thus, you are more closely synchronized with the DAQmx code portion.

I hope this will help you. Please report if you have any questions about the code or its implementation. Good luck!

-

Hello

I currently have the following equipment:

cDAQ-9178

OR-9401

OR-9219

I use the module OR 9401 to drive the output PWM signals is calculated by a PID controller in two controlled thermal systems. I use the NOR-9219 module to measure temperature, such as remote sensing by thermistors. These temperature values are used in my PID controller to calculate the error.

I am now interested in measuring a number of other temperatures on my device using thermocouples (these temperatures are necessary only - no controller action based on them). 9219 module is ideal for my PID controller, that I can use to detect the very precise Thermistors, but it has only 4 entries. I'm considering adding a NI 9213 Module to my setup to activate the additional analysis that I need... My question is this - this module will be compatible with my setup? for example can I simultaneously run two analog modules (9219 & 9213)? Is it reasonable to try to make the PID regulation and this extra temperature monitors simultaneously?

Thanks in advance for your comments!

See you soon!

Hello JB_1,

What is are describing is undoubtedly reasonable and feasible with the hardware you have. 9178 has several Motors synchronization to analog input, so you can configure separate tasks for two different modules if you want to acquire simultaneously and at different rates.

-Christina

Maybe you are looking for

-

Duplicate messages in Apple Watch?

Since the upgrade to the latest os from the watch, I get two alarms when I set my timer. The first is the regular advising me that the timer is done. Then about twenty or thirty seconds later, I get another warned that the alarm is over! I use the ti

-

Where is the pin of the NI 9401 land?

Guys and girls, It's a simple question, but where is the land of a NI 9401 pin? I see here (last page) the PIN on the module, but I do not see a GND port. Just connect to the ground of the signal to a port in NC? Or a COM port? (this means 'common')?

-

Windows Update failed to install an "Update priority" for months.

Microsoft Office Access Runtime and Data Connectivity 2007 Service Pack 2 (SP2) will download but not install. Error code: 0xA97. Difficulty It Center Microsoft says he saw an error and repaired, but not the update install always.

-

Error, you must be an administrator to run a console session using SFC

Original title: vista administor have windows vista Home premium and it may seem silly, but how to administer privileges. Am the only one on the laptop so I thought I got them somehow, but not so much that when I tried to invite her command of my I g

-

See description for my question