Number of series USE labview VI

Hello guys,.

Please, I'm trying (in vain) to use the serial number of the field USE to the test for labiew VI. I need to use the serial number in the string field (simple extreme). But I do not know how... Please I need help.

Thank you

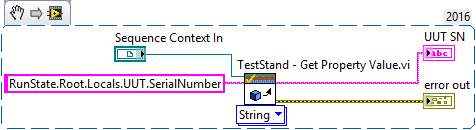

Try something like this:

You'll need spend the ThisContext in the VI when you call it from TestStand.

Hope this helps,

Trent

Tags: NI Software

Similar Questions

-

How to transfer files from PC to PC via a serial port using labview

I need to transfer files (.txt, .doc, .xls) from PC to PC via a serial port using LabVIEW. Is it possible to transfer files, if so how to transfer?

Yes, it is possible to transfer files with the serial port using LabVIEW. The files are just collections of bytes and the serial port is good enough in the expedition of the bytes from one PC to another. You must connect the ports series with a null modem cable.

First, take a look at the example of serial communication. In LabVIEW, go to the Help menu and select «Find examples...» ». From there, you can search for "serial" or navigate to hardware input and output > series. Select «Write series base» and Read.vi Try this example to gain confidence on the serial communication methods.

Then it's time to learn how to read and write files. For this, the examples might be somewhat confusing as they deal with files that are presumed to have data of a specific type in them. I would recommend just familiarize yourself with the functions in the file e/s palette. Specifically, familiarize yourself with the following functions.

- Open/create/replace file - on the side of your destination, you will need to create the copy of the file you are trying to transfer

- Close the file - when you're done reading or writing to a file, you must close it. It cleans the memory used and finalizes write operations that are still floating in the write buffer.

- Read a binary file - is the best way to play a file when you don't really like what type of file it. In your case, you just want to get these read bytes and sent so they can be written down instead of destination.

- Write to a binary file - next to the destination, is what will store the bytes in the file that you created with the number 1.

- Size of the file get (under the range of the advanced features of file) - you need to know how big the file is, so you know when you are finished.

OK, so once you are able to create files byte write and read bytes from existing files, you can move forward.

I suggest the basic method is to have the user specify a source file on the source PC, and a folder on the destination computer. Then find the size of the source file using the number 5. Divide this number of size by the number of bytes that you want to transfer to the times. The series pads are usually around 32 k (if I remember correctly) in order not to exceed that. Now start to send data by reading a number of bytes and this string output wiring to the feature of writing VISAS. On the side of destination, you will want to monitor the serial port for bytes and read when they arrive. This string of yarn to the writing of the function of binary file to add them to your destination file.

This is the basic outline of how to do it. He needs to not to overload him write and read buffers on the serial ports. Initially, you can use delays on the side sending to make sure that the side reading has enough time to digest. To make things faster, you can bring in a control of flow.

If all that sounds a little intimidating, there are there Alliance member companies (such as the automation of PrimeTest) who can write this code for you and even provides a turnkey for you solution.

Happy wiring,

Dan press

Certified LabVIEW Architect

-

float to bytes conversion using labview

in the project of the University to number of float serialy using labview. I don't know how to convert his individual bytes actualy I want to encode float in its float bytes. kindly help me in this regard

Send "bytes" is usually done in the form of strings. Just use catalogued with the disconnected type entry (or use "flatten chain").

To get started, simple would be to use the finder example in LabVIEW and search for serial communications.

-

How to program using Labview to an accelerometer

Hello:

I got an accelerometer which has digital I2C/SPI serial interface, so I bought a USB - I2C converter for data acquisition. I would like to know if I can use Labview to acquire data of com port and also program for the accelerometer to capture the data of the axis z. I have a box of white myDAQ NOR but SB. says that it is not an appropriate device to acquire before I2C/SPI signals. The datasheet of the accelerometer is in the accessory and the specification of the converter is this link: http://www.robot-electronics.co.uk/htm/usb_iss_tech.htm .

I hope someone can solve the problem for me. It is best to use the software labview for me because most of my project work is based on that.

Best regards

The f

Good and bad news. You have an accelerometer that 'speaks' I2C or USB to I2C converter, so if you connect both of them, you can send 'orders' of your accelerometer easily of LabVIEW by using communication series live that's the good news. The bad news is that it seems that you need to address your accelerometer using calls very low level, a work, I certainly don't want to face! This crys on a 'pilot', a middle piece of equipment that does all the "hard work" to take a high level order ("Please tell me the acceleration") and he translates things your device includes (including the Setup program, records, calendar, packing and unpacking of the bits and bytes, etc.).

Bob Schor

-

Deal with failure when using LabVIEW 2011 and DSC MODBUS communication

I'm currently reading from operating records a PLC with MODBUS/TCP. I confirmed that the PLC will update the values and in response to a MODBUS communication correctly by using a third-party program called Modbus Poll. However, when I try to query the PLC using the LabVIEW shared variable engine, I am unable to read the values of the same addresses that I consult with Modbus Poll.

My installation is simply to a PC directly connected to the controller via Ethernet without a router between the two. I'm using LabVIEW 2011 SP1 with the DSC module.

I opened the Manager of distributed systems OR to display the State of all variables in the Modbus Library that I created, and I noticed that the ILO CommFail permanently the value 'true '. All other variables with a 'read' access mode signal "failure of process". I tried to restart the process and stop and start the local variable engine without success. I also restarted my computer several times to see if any services did not exist, but this does not appear to have solved the problem.

Finally, I resorted to listening to communications on the network card I have the PLC connected via Ethernet using Wireshark and found that while Modbus Poll communicates with PLC, number of MODBUS and TCP packet is sent and received. However, when using only LabVIEW or the DSM OR communicate with the controller, there don't seem to be any communication on the network card.

Something that may be interesting to note is that I could communicate with the PLC and to read values with the DSM just once, when I understood everything first what address I should be reading of. All of this has stopped working shortly after. Prior to this, 'CommFail' was not generally set to 'true' with my current setup. Thinking it was my firewall, I have since disabled my firewall, but this seems to have had no effect on the problem either.

Any help on this would be appreciated.

So, I thought about it. It turns out that the IP address of the server i/o MODBUS must be set to the address of the MODBUS slave, not the local computer. The address of the i/o MODBUS server is defined by the navigation in the Explorer window projects, expanding the variable engine shared library for MODBUS and right click on the server MODBUS (for example Modbus1) item and select Properties.

In addition, the addresses seem to be shifted by + 1.

Thanks for the tip so.

-

Do another counter for usb-6008 VI using Labview 8.5

I want to create another counter for usb-6008 using Labview 8.5, it is necessary to calculate the two gears simultaneously.

The best way to proceed is to use the meter. The counter counts

signals without having to interrupt the system or use the USB bus.

When you ask the number of ticks that saw the meter, one

request is thrown from the CPU to the USB line to the 6008, which then

request counter "ticks how have you seen? This number is

returned on the USB bus, goes to the CPU and display on your

screen. Given that the DIO lines on the 6008 are software timed, it is

no way to guarantee that the data back to the central unit is

deterministic. The conceptual difference between software-controlled

DIO (that nondeterministically returns an entire stream) and a

meter software-tick-application-controlled (which returns a unique number

with the number of ticks) prevents us from using the DIO lines on the

6008. the best way to count more edges is buying more 6008 s.

Another possibility would be to buy a PCI card to counter such as

the PCI-6602, who owns 8 counters. Most of the counters we offer in the

USB form factor is 2 per device. -

NEITHER CVS using Labview Linux?

Hi, I have a CVS here, as well as 1455 development under labview linux machine. I've used MAX to set up this CVS, but it seems that my labview is not MAX, and I can see on the site it seems to be available for Linux. Could someone point me in the right direction to set up/use my CVS using labview linux (I've got installed 8.5).

You need to write code CVS to turn an image into a table of number using IMAQ ImageToArray.

Then, use the shared variable or TCP/IP to return data to the host VI.

However, there are two things to remember:

1. an image won't be like in real-time, as show on VI target itself.

2. because the Vision Development Module does not support on Linux, all the processing of the image on Linux must develop in yourself.

-

Printing of barcode using LabVIEW in Zebra GT800

Hello

I GT800 Zebra printer and I am trying to print a barcode 1 d with label using LabVIEW. I connected my printer via a USB port. What commands EPL must I give in order to print the bar code?

Well, before I was using .net and a printer connected in series, and we just called a shell command to copy the file on the com port with a command like "COPY /B PRINT. PRN, COM1.

I don't know which would be too much work to LabView, but there may be more elegant ways. I've never done no direct printing of labview so I don't know, but a quick bit of Googling (which I'm sure you can do it yourself as well as I can) seems to suggest that using the exec command vi system is the way to go.

To access a port USB printer can be more complicated. One way is to share the printer on the network and then map to an LPT port with a command like somethng "net use LPT1-

" from a command prompt (you can view the help on this command, because it comes just from memory) - then it becomes directly available on the back and you can use the COPY /B LPT1 command to send your file to him. ". If someone has a better suggestion for sending data to Labview to a printer, then I would like to know.

-

Impossible to acquire the lock on Fluke 45 COM1 series in LabVIEW

When the ECHO of multimeter Fluke setting is enabled, the following occurs using the Panel to test VISA OR max:

- In the VISA sign, a write command is sent to write * IDN? \r to the multimeter. No error, the DMM accepts the order.

- In the VISA sign, a reading command is sent and the DMM previous writing echoes (* IDN? \r) command to the VISA sign

- In the VISA sign, a reading command is sent, then the DMM shows the output of the command "write" (FLUKE, 45, [redacted] sn, D1.0\r\n 1.7)

- In the Panel VISA, a read command is sent, and then the DMM indicates that the "write" command has been received and executed successfully using default BOM of the DMM (-online \r\n)

Note that this is quite the same when ECHO is turned off, except that step 2 does not occur.

Now, it's quite identical to the output during the next show the * IDN? order Tera Term:

* IDN?

Fluke, 45, [redacted] sn, 1.7 D1.0

=>

(Tera term, does not display the CR (\r) or line feed (\n) as does the VISA Committee).

Thus, it would seem that the VISA panel communicates with the DMM in the same way as terminal, it is simply not actively reading such as Tera term and requires the user to request a read line.

What I don't understand is the difference between the behavior of the DMM when you use the Tera term or the Panel test VISA and when using LabVIEW.

When communicating with the DMM in terms of Tera or the VISA sign, the digital multimeter answers ranging from 1 view state to indicate status 2 (see images below). When you try to use even the simplest example communication series live or the driver plug-and-play Fluke screws, the DMM remains to view state 1. Note that the change of State 1 to State 2 happens only after the launch of a connection in Tera term or the VISA sign; so, I think I'm having a problem where LabVIEW is unable to acquire a lock for communication with the instrument series.

If someone has some, please let me know if you have a way to solve this particular problem.

Display status 1:

Display state 2:

-

Determine what are the cards OR are installed on a computer using Labview

Hello people,

I hope that it is a matter appropriate for this forum.

Is there a way to programmatically determine the cards OR are installed in a computer using Labview? We have a limited number of test for material Exchange computers sometimes. I would like to write a collection of Labview applications to know what hardware is installed and then perform some configuration based on the hardware settings.

Best regards

Chris

Hello

Looks like than what you may have here: complete peripheral extraction and list of channels dynamically.

-

Hello!!

It comes to my school project. I need to implement the design to send sms using labview. And I use iTegno 3000 modem and I have no idea where to start. Can someone has a basic idea for me? All the specific commands to use for the modem I use?

Thank you very much for your help

Good day! looking forward to all your kind reply...

Your sequence of structures aren't absolutely necessary and are just getting in the way so delete.

You do not have a phone number - the yyyyyy is not all correct and you do not send a CTRL-z character. You send the text "ctrl + z". Set the string to display hexadecimal constant and enter 1.

-

test transistor using labVIEW project

Hi all. I'm new in labview... pls guide me... Thank you...

I am a student and I have to do a project on labview, my project is: "DEVELOPMENT OF AUTOMATED TEST SYSTEM for TRANSISTOR USING LabVIEW.

I already installed labVIEW 8.5... can someone give me a tips to get started on my project?

I need to find a coding for CC, Osciloscope and Transistor power...

Thank you...

Start by writing a project plan.

What do you want the program to do? What are the tests that you must run on this transistor?

What are their contributions, what are its results?

What are the series of steps you have to do to go from A to B?

What material did you use? You mentioned a DC power supply and an oscilloscope, which brands and models? You use data acquisition cards?

-

Hello

I have to synchronize two software to 20 ms of precision, the timestamp of labview first single use (128bits, 1904 ect...) and cannot be changed.

and the second is written in C++ using DAQmx, I find the trick of subtracting the number of seconds of a struct tm classic.

But it's not accurate enough for me.

The only solution I found, is to use Structure SYSTEMTIME and use the same round as the struct tm.

But I do find it very nice, so is it possible to use the same routine as labview in a classic C++ program (or cvi classic)?

Thanks in advance!

Eric

Hey Eric-

I don't know if you are still working on it, but I thought I would mention the time CVI API absolute in the library of utilities. It uses the Format binary time of National Instruments, which I think is what should use LabVIEW and should meet your needs.

NickB

National Instruments

-

Ho fatto non trovo più pasticci he mio number di series by willing e switch Creative Cloud, come posso fare?

!

creating cloud does not have a serial number. It uses your adobe id.

Download the creative cloud desktop application (after signing with your adobe ID), apps download Adobe Creative Cloud | CC free trial Adobe

and use the desktop application to install your adobe creative programs of cloud.

If you already have the cc desktop application and you will need to update your adobe id, connect, disconnect | Creative desktop application Cloud

-

Screenshot of Tektronix MSO4104B using LabVIEW

I am trying to acquire a screenshot of an oscilloscope Tektronix MSO4104B using LabVIEW. I am currently able to collect data from the device and have a waveform displayed on my front of VI. However, for various reasons, our preference is to capture the actual screen shot of the scope.

I have reviewed the reference for programmers for this camera and have done countless searches on Google for an answer, but have not been able to find a solution. It seems that a few people were able to reach on OTHER Tek scopes by sending a hard copy through the port of communication (GPIB, USB, Ethernet, etc.), but according to the reference of programmers for this particular device, it seems that he will send a paper copy of an installed printer, rather than simply as a stream of data to the port which can be read using VISA controls.

The other solution I've seen is to record the screen turned to a flash drive, and then copy the file via the port to the PC. However, none of these solutions seems to be available on this device... it's one of the more advanced scopes makes Tek... I can't believe it's so hard! Help, please!

Maybe you are looking for

-

I have the same problem enter password administrator or power on password. Disable the 68253840 code shows. I tried to participate get the battery cmos as suggested on other Web sites, but it's hard to disassemble. I used the enemy months laptop then

-

Satellite A300 PSAG4E - no sound when you plug an electric guitar

Hello everyone! I have a very difficult problem. I've got model Satellite A300, PSAG4E its short no, with Windows XP SP3 installed. The point is that I need to plug in an electric guitar to my computer and once it is plugged in, RealTek HD sees him b

-

MAX does not see the devices and interfaces

Hello Just got a laptop computer to support the lab and installed Labview. For reasons that I don't have understands THAT MAX does not see the com and USB ports in the laptop. The IT Department gacve my rights to admin ID. Any ideas what's happening?

-

I am trying to burn a movie that I made myself using Windows Movie Maker on a DVD, but whenever he progresses to 80 to 90% at the end I get the message that burns if not possible due to a disk error. I have tried many different disks.I use Vista Home

-

DeskJet 6940 Networking questions

My installation disc is long gone. I need this thing through wired laptop Mr. puppy network. We are both using Windows 7, which, thanks to the whims of the gods, IS NOT wireless network on this printer. Loki minions just don't know why. (For the reco