Why do my pci-6052e configured as traditional daq and daqmx in MAX?

I have an old computer of three year with 1 GB of RAM and a 3.00 GHz running Windows Server 2003. It has already been used for experiments of movement control and has a 7333 motion control card and a PCI-6052E. Now all I want to do is sample data of a pressure sensor and a flow meter using the PCI-6052E, but for some reason, this card is configured in MAX as a DAQmx device and a traditional DAQ (Leagcy) deivce. Unfortunately, when I write the LabVIEW 8.2 VI, the only available data acquisition tools are DAQmx and Max my two instruments are installed in traditional DAQ.

If there is only one card PCI-6052E in the computer, why MAX card PCI-6052E called dev3 DAQmx and a card PCI-6052E dev1 in traditional DAQ? How can I fix?

Cpesko,

I am happy here, you have a few things working under Windows Server 2003. We do not however have any software under this OS except what is listed here.

DAQmx and TDAQ are 2 different drivers and this is the behavior expected that devices that support both would be present in the title of each driver.

Tags: NI Software

Similar Questions

-

Traditional DAQ and DAQmx data representation

Hello

I use a card PCI-6013-NOR and used DAQ_Op and DAQ_Start to acquire the data of the device (with game 1 win), who have a CCD camera to acquire data.

I migrated the DAQmx application, it works fine, but the intensity of the curve drawn using data is lower than expected.

During the migration of the old code, I replaced the logic below DAQ_Op

/*------------------------------------------------------------------------------------------------*/

TaskHandle ulTaskHandle = 0;

DAQmxCreateTask ("", & ulTaskHandle);

Double dMaxVolt = 5.0;

Double dMinVolt = - 5.0;DAQmxCreateAIVoltageChan (ulTaskHandle, "Dev1/ai0", "", DAQmx_Val_Cfg_Default, dMinVolt, dMaxVolt, DAQmx_Val_Volts, NULL);

/ * This function handles various combinations to select the signal.

* - Select_Signal (1, ND_PFI_2, ND_IN_CONVERT, ND_HIGH_TO_LOW)

* - Select_Signal (1, ND_SCANCLK_LINE, ND_SCANCLK, ND_LOW_TO_HIGH)*/

RouteSignal();

DAQmxCfgSampClkTiming (ulTaskHandle, NULL, dSampleRate, DAQmx_Val_Rising, DAQmx_Val_FiniteSamps, ul64SamplePerChan);

DAQmxStartTask (ulTaskHandle);

/ * Allocation of memory for data acquisition. */

Double * pDataBuf = new double [ulCount + 1];long lSamplesToRead = (long) ulCount;

long lSampsPerChanRead = 0;DAQmxReadAnalogF64 (ulTaskHandle, DAQmx_Val_Auto, DAQmx_Val_WaitInfinitely, DAQmx_Val_GroupByChannel, pDataBuf, lSamplesToRead, & lSampsPerChanRead, NULL);

If (ulCount! = (unsigned long) lSampsPerChanRead)

{

}

on the other

{

for (unsigned long ulIdx = 0; ulIdx)< ulcount;="">

{/ * psBuffer is a short table.

* Here, I'm trying to convert and copy the new buffer (double value)

* to the old buffer (short values)

*

* I guess that old values will be in the millivolts range.

* To convert the values of v of the buffer in millivolt I am multiplying by 1000

*

* I don't know if it is true.

*(psBuffer+ulIdx) = static_cast

((*(pDataBuf+ulIdx) * 1000));

}

}I'm not sure whether the conversion I did new buffer for old buffer is true. I need to create a DAQmx_Val_FromCustomScale to get the same value DAQ_Op returned?

Could you find something wrong with the logic? How can I get the same DAQ_Op value returned by the double buffer returned by DAQmxReadAnalogF64() is there any best mechanism available?

concerning

Praveen.DA

The reason for your bug is that you apparently did not understand what does the DAQ_Op function. In help for this, it is clearly stated that the data returned is I16. Your choice of data F64 was an obvious conflict with how you have porgrammed traditional in DAQ board. The Council resolution doesn't really matter. The big difference is set to scale and without scales.

-

Traditional DAQ against DAQmx Counter

I'm trying to convert an existing legacy application written in LabVIEW LabVIEW 2012 6. I have a problem with a traditional Daq counter. Specicically the VI "event or time meter Config.vi. In the attached VI, you can see that 1 meter is configured to count the cycles of an internal signal, not a PIN counter SOURCE signal. This configuration generates an integer for each cycle of the internal signal: every 10 microseconds in this case. I can't find a way to replicate this feature in DAQmx. I use a DAQCard-6062E (PCMCIA Slot) card in a Dell D620 Laptop. I tried to attach a fully functional VI, but get the error 'the content of the attachment does not match the type of file.' to fix this I had to fix a JPG image. I've included comments in VI to clarify things. Any help appreciated. Thank you.

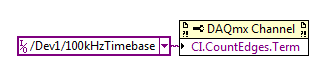

In DAQmx you can achieve the same result by setting the terminal entrance for a task of edge to the time base County internal 100 kHz:

The 100 kHz Timebase is considered to be a "Advanced terminal" (don't get started me on the topic) so see in the dropdown menu, you must right-click on the control / constant and select the appropriate name of I/O filtering option.

Best regards

-

Difference between DAQ and DAQmx for acquisition of data PCI 6534

Hello

I use the PCI DAQ 6534 card for my digital I/o transfer. I am beginner in the labview.

I want to store the data coming in memory and the reading of the data at the level of the trigger.

I have seen the examples in the labview. Some have used DAQmx and DAQmx read write that screws and some have used the confg DIO port and all...

So I want to know the difference between these two. For my application that I use?

Hey Bo,

First of all, I would recommend that you discover the NI 6533/6534 for NOR-DAQmx help. You may be able to find some of your answers in this help document. Now for what you try to do in your application, it looks like you are only buying data. If this is the case, with the 6534, the device acquires data in memory shipped as soon as the DAQmx series start task VI, as long as you don't start hardware triggers have in place. If you have a trigger of starting material, then will make the purchase of the aircraft after the DAQmx start task VI and only after you receive this material trigger. If you call not the DAQmx Read VI, then the data will be stored in the memory board for you, as the driver manages this data in the on-board memory storage, until reading DAQmx VI is called, which at that time, data is transferred to the Board of Directors in the memory of the computer. Once you get it in the computer's memory, you can do whatever you want with these data, as this graph or treat. If you look at the sample programs (which have been mentioned on how to find those in a previous post), you can find an example that little shows you how it works. One of the examples that you can check is called reading Dig Port-Ext Clk.VI. In this example, it sets up to read a finite number of samples and then starts the task. If you set a breakpoint on the line of the error after the VI begin, the data will be acquired in the amount of on-board memory. Then when you cancel the break of the VI, data will be extracted from the amount memory embedded in the memory system with the reading VI DAQmx. Again, the pilot takes care to put the data in the memory board for you once you start the task.

I hope this helps. Please let us know if you have any questions or concerns about this issue. Also, certainly, discover and try to run all the programs related to the 6534 examples so that you can learn how the equipment works and how to use features to do what you want your program to do. Also, be sure to read through the help on the 6534, as well as the help of VI documentation to learn what makes each function. Thank you and have a nice day.

Kind regards

DJ L.

-

Tradition DAQ installed but not available

Hello

I have a system that had LabVIEW executable v6.0.2 running with 6.9.3f3 NOR-DAQ with a PCI-6052E. I have now installed LabVIEW 2009 with NOR-7.4.4 traditional DAQ OR DAQmx 8.9.5 on this system. My 6052E appears in MAX under NOR-DAQmx and NOR-DAQ traditional (old) devices, but under the legacy, the button 'Test panels... '. "is grayed out and if I get the properties of this device, tab 'System' of later dialogue has the resources box in gray gray as well as 'Test resources' and 'Run Test panels' buttons. I tried to reset the device under DAQmx, but it does not help. I ran a self-test of the 6052E by right-clicking on the device under DAQmx and happening.

Another problem I noticed is when I try to run any traditional LabVIEW DAQ example, I get the following error repeatedly: "load error"C:\Program NIUninstaller Instruments\LabVIEW 2009\vi.lib\Daq\lvdaq.dll". A dynamic link library (DLL) initialization failed. "This happens for each traditional DAQ VI who is trying to load.

Examples of LabVIEW DAQmx load and run fine.

This looks like a corrupted installation of NOR-DAQ (Legacy). My goal is to get my code that runs under the latest NOR-DAQ (Legacy) and then transition to DAQmx. What is the best way to proceed is this new OR-DAQ (Legacy) to run?

Thank you

Greg

You have fixed the problem by repairing the NOR-DAQ 7.4.4 (legacy) install via Windows ' Add / Remove programs.

Greg

-

Traditional speed DAQ vs DAQmx comparison

I currently use four 4 boards of 16th-1 MIO PCI National in the HP running Windows XP workstation test simultaneously four 4 medical devices at a time. We currently use traditional DAQ and LabVIEW 8.2 to test our products to the main line. Our test software is strictly controlled and requires reesources important for validation when changes are made. We bought the LabVEIW 2010 and it supports more traditional DAQ. We know that somewhere in the future we will make the transition to DAQmx and LabVIEW 2010.

I need to perform a cost compared to the benefits of the conversion of the test of LabVIEW 8.2 and traditional DAQmx and LabVIEW 2010 DAQ system. If the profit is high enough I was able to hire a consultant to expedite this process.

I know there are many variables that factor in speed, and I know that I have not provided details, but can anyone provide rough estimates. Is this 2%, 10%, 20%? What is your best guess/estimate?

Thanks in advance

Hi Int_man,

Traditional DAQ 7.4.4 does support LabVIEW 2010, but to install traditional DAQ to a version of LabVIEW at once more, you have to follow a procedure described in the readme file. Traditional DAQ does not support newer operating systems such as Vista or Windows 7, and it does not support new hardware such as M or X series. Given your validation needs it sounds like you might not be upgrading your operating system or hardware in the near future, but if you ever decide to do, you would need to spend to DAQmx.

Performance is a little tricky... You could see a perforamnce increases with an upgrade to DAQmx, but this depends entirely on your application. I wouldn't feel uncomfortable providing any kind of estimate of the increase in performance without any information on the application itself. For example, DAQmx provides thread that can often be used to increase the performance of the application at the same time, but if your application writes past most of the time of digital static call in order, you may see a performance decrease slightly because of the overhead of a cheque that has been implemented in DAQmx in order to avoid the double-driving lines. Overall, most of the functionality has improved in speed, but it is not possible to say outright that "move to DAQmx will give X % increase in performance" in all cases.

That said, if you have to go through a validation anyway it might be timely to review the whole of the system as a whole (including the DAQ equipment used). Unless you are implementing your comments or need to input user scope, the speed of the software driver calls could be made essentially irrelevant if you are able to use the material that allows buffering and trigger your necessary inputs and outputs. As someone who has been loaded to optimize the suboptimal systems (if necessary), I strongly encourage you to review the entire application as a whole and where the greatest improvement.

Best regards

-

Is there a DAQmx function to duplicate the traditional DAQ "Index.vi channel".

I've been converting an old app using traditional DAQ to DAQmx. It's a complicated piece of code and makes installation of all available channel group config, then the user selects the specific ways to acquire data on. It uses the "Index.vi channel" to achieve this. Is it possible to replicate this feature in DAQmx, or will I have to rewrite the whole mess? Thank you.

Thank you aNltaB. I was able to implement a task with the necessary channels for each thing that I did and circumvent the need to configure all channels and then indexing them. I didn't know how it was all rooted in the program, but make the separate tasks seems to work well. As far as I am concerned, this issue is resolved.

-

NOR-DAQ traditional to NOR-DAQmx

I am a neophyte of LabVIEW. I inherited a previous employee long gone from the company, so that I work a LabVIEW project. The project has been written using NOR-traditional DAQ and I need some update OR-DAQmx so that it is 64-bit capable. Of course, I ran into trouble with the VI first that I try to put in level.

This VI was built with LabVIEW 2011 SP1 and I need to replace the Config AI, I start, I Read, Index channel, control and HAVE clear screw with their equivalents of NOR-DAQmx. Upgrade to SP1 2013 LabVIEW is possible if that makes things easier.

Now here is the tricky part. I want to keep the terminals on this VI even if possible. This VI is used in several places and a few different programs and I want to make the change as minimally invasive as possible. If possible, I want the changes must be made within this VI.

I am looking for any help and or advice. Thank you.

First, abandon all hope to keep the same connector components. It is possible, but it's foolish to try. (Just trust me, OK?)

Read these articles in the knowledge base

http://www.NI.com/white-paper/3021/en/

http://www.NI.com/white-paper/4342/en/

What you're trying requires skills usually not developed in a neophyte of LabVIEW. (And you start with the 'Spaghetti' code - this is not 'Fun') Do an internship of audit and meet with your representative local of NOR. Chances are that some local expert advice will point you away from some serious mistakes.

Take care

-

Hi all

I had problems to understand the program to someone. Could someone of you help out me?

These programs are written in Labview 6.x and integrated in a software, which can detect the DAQ (PCI-6052E) card, a series of input modules (SCXI-1520) and then collect the data from the input modules simutanously.

Issues related to the:

1. how to make a menu drop-down list all the modules detected, and then the customer can choose between them? Looks like the former programmer do that with property node...

2. now, we have a new input module (SCXI-1530). However, the software says it can only suppor SCXI-1531 and cannot detect SCXI-1530, although MAX can do. The difference between SCXI-1530 (4 channels) and SCXI-1531 (8 channels) is the number of channels. It is possible to modify the software and make it compatible with SCXI-1530?

All ideas are appericiated.

Thank you

Hi oly.

You're right, aid for SCXI Information.vi does not have the types of module for SCXI-1530/1531. The function C (SCXI_Get_Module_Info) in the Start Menu > all programs > National Instruments > NOR-DAQ > traditional NOR-DAQ function reference Help contains 48: SCXI-1531; 50: SCXI-1530.

Brad

-

limited on PCI-6052E sampling frequency

I'm trying to measure with two channels with a PC containing a NI PCI-6052E card that is capable of 333KS/s on LabView 8.2. With two channels each channel must be able to 333KS/s / 2 = 166.5KS / s. everytime I try to set the sampling frequency above 94339 Hz I the following warning and the vi no longer works.

WARNING 200012 occurred DAQmx start Task.vi:1

Possible reasons:

Clock speed specified is greater than the maximum ADC conversion rate. ADC invaded errors are likely.If I place a similar task in the Measument and Automation Explorer and I can easily make two channels measures to 160kHz without error. Above 166kHz I start getting the same caveat (200012). The code that I use calls first DAQmx create Channel.vi, then DAQmx Timing.vi and finally DAQmx start Task.vi. Everything works fine and I did measuements, but I can't rise above 94339 Hz sampling rate even if it should be possible.

I just looked and I can't understand the issue here.

Dear Voyn,

I thank very you much for your message on our forum. If you create a task for a single channel, you can get a higher sampling rate? Are you able to reproduce the same problem with an example from the finder example? Go to hardware to go end tab selected and output-DAQmx online-online-online-online Acq Cont voltage analog measures & chart voltage-Int Clk.vi

You can select several channels as well. If it shows the same behavior; which driver DAQmx do you use?

Best regards

-

The PCI-6052e does support I2C or SPI communication?

Currently, I am trying to build a data acquisition system to test, among other things, SPI and I2C devices verification of characteristics and surveys of behaviour without advertisement above the different temperatures. The DAQ card that I use is the PCI-6052e as well as the SCB-68. It has 8 ports DIO, but can someone tell me if it will support SPI or I2C? Another post in the forum indicated that it will not support 16-bit SPI, but for my application only 8 bit is necessary. I am not opposed to research in other materials DAQ, such as the USB-8451, but would like to see if the 6052e can do the job first. If she can't, then my next question would be; Can the 6052e and USB-8451 operate in parallel which allows me to use both analog and digital functionality? Thank you

If you will try little he hit then you might find these links useful:

-

Why wireless zero configuration service automatically stop and I start it manually?

Original title: wifi Poblem in xpIn Windows Xp wireless zero configuration service automatically stops and I start it manually I want to know why this service stopped automatically help me solve this problem

Hello

- Did you changes to the computer before the problem occurred?

I suggest you to follow the steps below and check if it helps.

Method 1: How can I disable wireless configuration and enable Windows XP Wireless Auto Configuration services: http://support.microsoft.com/kb/968682

Method 2: Also I suggest that you install the updated drivers for the network adapter on the computer by visiting the manufacturer of the network adapter and verify that it works.

How to manage devices in Windows XP: http://support.microsoft.com/kb/283658

Hope this information is useful.

-

Lost XP and reinstalled. Now the drivers for the Ethernet controller and a PCI Simple Configuration are not there. Can not find them, is there a place I can get these drivers.

Hello

I couldn't find the manufacturer's website to download the drivers. However, you can download the drivers from the link: http://www.via.com.tw/en/support/drivers.jsp

You can also check the links: information about the hardware devices for Windows XP drivers: http://support.microsoft.com/kb/319908

How to download updates that include drivers and hotfixes from the Windows Update Catalog: http://support.microsoft.com/kb/323166

-

How can I configure a PFI to high on a 6602 traditional DAQ board

Dear all,

I'm using LabVIEW 8.5 on 32-bit Windows XP with a data NEITHER the 6602 acquisition Committee. In the past, I used DAQmx but for compatibility with older software, I need to do a few simple things using traditional DAQ, which I never used. Specifically, I want to make a simple VI which affects 5 PFI high when the user presses a button and then low when they press a second time. How do I put 5 PFI for output and then write faithful to her?

Thank you

Ed

Dear all,

Apparently its also simple to use digital writing line VI. However, the non-obvious thing is the width of the Board 6602 32 port is not the default value 8. Buried in the LabVIEW help files is a list of widths of physical port to fall on. As the cave of bats. In the picture as an attachment to the super simple VI, I did the 16 designated PFI 16. Good to know.

Best,

Ed

-

Name of the traditional model DAQ and SCXI-1530

Hi all

I'm using Labview 6.1 and 7.1 of DAQ traditional. I'm working on a system with a data acquisition card (PCI-6052E) and several SCXI (1520, 1530) cards. The SCXI cards are installed correctly because MAX can detect all.

I want to do a program with traditional DAQ that allows to detect all SCXI cards and Show names of model on the front panel.

I found in Tradtional DAQ, there is a VI entitled "Get SCXI information", which returns the types of models of SCXI cards, something like, 50, 51...

I found in the help file on 'Get SCXI Information' VI there are some kind of configuration file saying 51 stands for SCXI-1520. What does the acronym for 50? Where can I find the full configuration file or can somehow I change it? As 51 means something else...

Any ideas are much appreciated... Thanks to you all!

This is a duplicate of the last post in this thread: http://forums.ni.com/ni/board/message?board.id=250&thread.id=53087

Maybe you are looking for

-

Before I float test this thing, all hope for my kernel_task fly?

I'm at my wit's end. I asked this question before but I had a temporary improvement, but those days are gone. I ended up having my machine to grind to a halt when I have any kind of video running, either with EyeTV VLC with kernel_task showing 500 +

-

How to create bookmarks on Mac OS 10.8.2 after installing a new hard drive?

At this point, I have no bookmarks or folders in Safari or Foxfire. I started with Foxfire and could find no way to create folders for the bookmarks. I tried the "show all bookmarks" in the menu "Favorites" and then hold down the 'Ctrl' key while tou

-

How to increase the strength of a WiFi connectivity

original title: problems with WiFi connectivity... OK, here's my problem. I currently rent an apartment on the ground floor in the same House as my owner. They have wifi. They also gave me the code to enable my PC pick up their wifi as a benefit incl

-

intallation of difficulties of download of photosmartC4480 Hp on line

Why cant I save online my hp photosmart C4480 device, with errors and the extreme, I went, can't scan with

-

Utility software update HP does not my Compaq Presario CQ61

Hello. I can't launch the HP utility software update from my laptop (details in 'topic'. It has been ongoing for 11/23/2011. My operating system is: Windows Vista Basic - 32 bit. Error message: error occurred during the processing of a message. Try