Analog voltage trigger

I'm using LabVIEW 7 on windows 2000 with the PXI-4461

I'm trying to have the labview read arriving through the analog input voltage but start recording data when the voltage passes a certain threshold value. I tried an example 'acquisition & graph continuous tension - analog trig SW. The graph displays amplitude on samples. I am looking for amplitude over time. Any help is greatly appreciated.

Thank you

SparkEE

No, it is not necessary to a xy chart. A normal graph displays a signal sampled regularly with time on the x-axis if you configure the properties of the graph for absolute time or regular. If you buy a type of waveform data, the chart uses the t0 and dt signals. Right-click on the chart and do of course ignore timestamp is not selected.

Tags: NI Software

Similar Questions

-

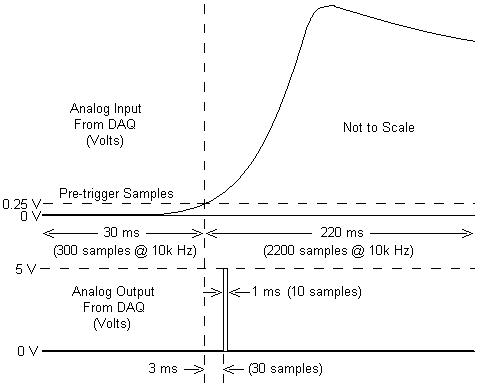

I am working with a combustion chamber and using a system of data acquisition (with the hardware OR SCB - 68) to read the pressure in the cylinder (such as analog voltage). I'm trying a pulse delayed, 1 millisecond to 5 volts of output once the pressure in the cylinder is high above 5 bar (which corresponds to an analogue voltage of 0.25 V). I would also like to record 30 ms samples before the trigger and 220 ms samples after the outbreak. The following image shows visually what I'm talking about.

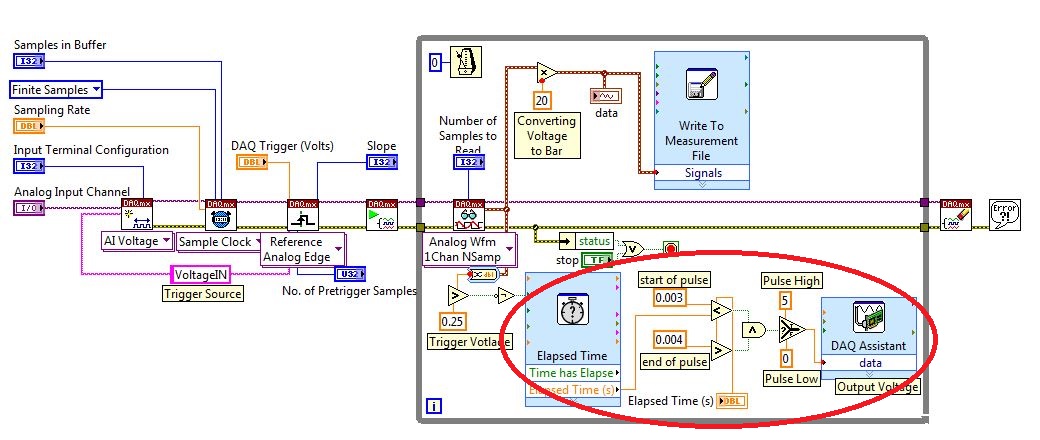

I created a LabVIEW VI (which is attached), but I keep running into 2 issues:

- When I run with samples finished after a period of time, I get error-200281which I don't quite understand.

- Using the Express VI 'Out of time' to keep time for the pulse I can not get a resolution of 1 millisecond, the pulse is not generated when I put the window between 0.003 and 0.004 seconds for high pulse (i.e. the resolution of 'Elapsed Time' seems to be too coarse).

I'm a beginner to LabVIEW sorry if my questions are trivial or my VI makes no sense, but I was stuck on this during more than a week. Any help would be greatly appreciated!

Thank you

Morgen

This isn't a good way to trigger a pulse.

Use a trigger DAQmx to send the pulse when your acquired signal exceeds 250 mV you specified.See this for DAQmx trigger:

-

Trigger SW analog voltage CONT Acq & graphic

Hello

In the example Cont Acq & chart analog voltage SW Trigger.vi It seems to me that if specify you a channel that relaxation comes on, then it would be a hardware trigger is not a software trigger. Why do call it a software trigger work?

I PCI6071E I want to trigger by sending in a channel if a pulse (63). Wouldn't that considered triggering material? If that is an example for this available?

Also I'm not clear on what they mean by the parameter ' Amplitude/hysteresis window' in the trip parameters. Could someone explain this to me?

Thank you!

-

Hello

How acquire and store the values of voltage DAQmx?

I tried several code example, but they can't get the chart. I don't want to chart. I want to measure exactly the analog voltage values and record these values - as an excel chart, that contains the selected channels and voltage values.

What the example code that I can use?

My hardware is NI PCI-6251.

Thank you very much.

-

Get the duty cycle of DAQ to analog voltage input module

Hello.

I'm new to labview. I have an analog voltage input data acquisition module. I try to get the duty cycle of a square (generated from a function generator). What is the best way to go about this? When I use the vi to acquire an analog wave cyclical report, the values are incorrect.

Post your VI as well as real data of your signals so we can see what is happening.

Lynn

-

Generate an analog voltage with amplitude variations

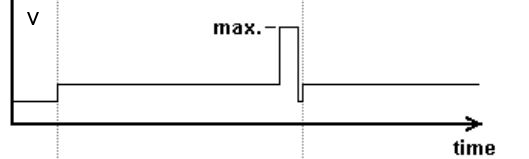

I want to generate a 0 - 5V analog voltage output that has a variable amplitude, as shown in the figure. The maximum voltage is 5V and low voltage a percentage of this, but I must not vary the amplitude during execution of VI.

With digital outputs, you are limited to two levels. Low and High. (1 and 0). Here are the outputs of the DIO lines as DC voltage levels. The two levels can be anything, but 0v is most commonly used for bass and 5v is used for the great. This is called (as well as some other features) TTL logic.

There are some cards that allow you to choose the digital voltage levels, but your all-in-one does not provide this functionality.

You could do something similar with digital, where you have only used the 0v and 5v levels.

You are absolutely right that software control timing is less precise than the timing control material, however, if you did a spot of digital output in this way and set it up to do the finished samples or continuous, it would use a material timing and would therefore be very accurate (in accordance with the specifications in the technical data of the device).

-

is it ok to connect two outputs analog voltage in series?

Ok... I have a PS-210 FieldPoint... basically an analog voltage output 0 - 10V, 200mA per channel (with additional external power supply)... my question is... can I plug two channels in series? Love how I can put two AA batteries in the series... and then to double my blood pressure? and then check my two separate channels and the sum of the tensions would be assujettirait I have my load in?

Thank you!

No, you can't. The channels all share the common side of their outputs. If you've tried to hang them in the series, you have wind of short-circuit one output from the ground.

The reason for which you can do with batteries is that the tensions are floating. There is no common reference between the negative terminals of both batteries.

-

Help design a trigger for an analog voltage signal

Hello guys,.

I have a real problem one design trigger for an application, what I do is to power a motor and measure consumption current and voltage during each operation. What I would do is to begin to acquire the signal once the voltage rises to a certain value and finish when it falls to a certain value. The equipment I use is a cDAQ 9178 with a NI9205 and 9221 modules.

Any help / samples / detailed explanation will be really appreciated. I have no idea on how to work with the outbreak of the vi in Labview.

Concerning

SergeArmz

Finally after a lot of research, tests and many developments, this is a VI that I developed and who is able to do what I was looking for. Thanks to the guys who helped me out to understand how solve my problem.

For all those who may have the same problem I had, I enclose the VI.

And of course if you can improve on what I did will be great, I think it's the purpose of this forum

See you soon!

SergeArmz

-

Blocking of blue screen with the analog voltage (WinXP, PCI-6251)

Hello

I'm looking to solve a problem of blue screen with my measure blocking

application, which I am developing with C++. Blocking seems manifest

a little random after a variable amount (500-50 000) of voltage analog

measures. My application needs to make a huge amount of these digitally

trigger voltage measures after a certain period of time, and I'm using a

unique

task to do. The task is stopped and started after a single measure

is

which is done around 10 000 - 100 000 times per second. For this

because I do synchronized with the PCI-6251 map data acquisition and

one

Ztec oscilloscope card. It seems that the probability of blocking could be

associated with

the frequency of measurements of voltage that I perform.The

the app itself is multithreaded, but I'm blocking concurrent access

TO

the card with lock - all access to the card are behind a single mutexlock, so simultaneous access is blocked. In any case, all data acquisition

access

o the map is initially a single thread, which is dedicated to the acquisition of data

operations.I also did stress tests with Ztec scope map, which does not

result

in all the problems. I also disabled in order of acquisition of Ztec map data

TO

Make sure that it wasn't the card scope, the origin of the problems - the problem

persistent, so this seems to point towards the direction of the nidaq map.The deadlock appeared when I used the original supplied with drivers

the

card. I installed the latest drivers (removed the device from)

' Windows

Device Manager and your application Measurement & Automation, reinstalled), but the blue screen still appears.Blue screen gives me a few debug data, but it does not mention any

files .dll or something that would be of course point to a specific file (driver). I enclose at least partially matching code snippets.

Hello again! I've been in contact with a local support person, who suggested that I have use DAQmx_Val_FiniteSamps instead of DAQmx_Val_HWTimedSinglePoint. I don't have any other changes, but this (see below) and the problem disappeared, so this seems to be an acceptable solution, because I don't see at all why not do this way. (Thanks Henry!)

DAQmxErrChk (DAQmxCfgSampClkTiming (task_reader, NULL, 100000.0, DAQmx_Val_Rising, DAQmx_Val_HWTimedSinglePoint, 1));

DAQmxErrChk (DAQmxCfgSampClkTiming (task_reader, NULL, 100000.0, DAQmx_Val_Rising, DAQmx_Val_FiniteSamps, 2)); -

NEITHER 9234 with quasi static analog voltage

Hello

I have a NI 9234 (4 channels + / IEPE 24-bit 5V) attached to a chassis cRIO module. This module is ideal for accelerometers and microphones where the tension is in constant evolution (ie; measures of variation rates).

I also have a module OR 9237 (4 channels 24-bit full-bridge module analog input) attached to the same cRIO. This module is ideal for measure variable voltages of strain gauges (quasi static and dynamic loads).

The attached graph shows the two channels, collected synchronously, but as you can see the (red trace) cell breaks down (as it should), but then drifts back to zero on its own, when in fact it should remain low just like the extensometer is beam. After all, the two sensors are physically secured.

Q1: Would that have something to do with AC/DC module 9234 internal coupling?

Q2: Is it really possible to collect "quasi static" ongoing tensions by using a NI 9234 module?

No explanation as to why this occurs, or if there is a way to remedy this would be appreciated.

Kind regards

Andreas

Coupling AC/DC must do a lot with your question. In mode AC voltages static will be fitered outside and the 9234 measure indeed only change voltages. In DC mode, the voltage goes directly to the AD converter and you can also detect static tensions.

A minute of Googling gave me the answer, this load cell electric piezo can measure dynamic changes, as any charge will escape the path the lowest resistance and the signal will go to zero after a certain time. I guess the other device you were using higher internal resistance (which is relatively low on the 9234), so it takes more time to what he flees, but he also took on the picture you attached your second try.

Here you can find more example under the title

"WHY ONLY DYNAMIC FORCE CAN BE MEASURED WITH SENSORS OF POWER PIEZOELECTRIC"

http://www.PCB.com/techsupport/tech_force

Andreas Jost

Technical sales engineer

National Instruments

-

How can I use my PXI-6115 meter analog signal trigger to generate pulses of frequency

I work on a PXI-6115 DAQ card and want to using the analog signal to trigger the counter it's generating frequency pulses. The manual says the analog trigger is supported, but I can't use an analog signal to trigger the start of work, in the test, I use the counter 0 to generate pulses and use the signal input port analog trigger PFI 0, can someone tell me what it is? My test VI. & error message appears in the attachment.

Best regards

If you read the error you can see digital triggers are the available trigger only when you use the output of the counter.

You can work around this by setting up a dummy analog input task which will trigger an internal digital triggering when he sees the right analog trigger.

See this thread for more details:

-

measurement of analog voltage tends to zero

Hello, I'm new to the forum see lab and Labview FPGA. First of all I would like to describe my system: I measure the voltage of the voltage inverteres-three with LEM - LV 25-400. Three analog inputs (I + and HAVE-) are connected to the LEM. I run the analog measurement of Labview demo program and it can measure the voltage, but donot values remain constant. He goes to zero and after some time goes to the correct value. My blood pressure never goe to zero. One can derive a little but almost constant. If I add the filter with high sampling rate, I had an almost constant value but miss the ripple values. I wonder if anyone can help me would be greatly appreciated.

with respect,

Marco

problem solved

-

Hello

I'm looking for different options for controlling an electronic valve. Order entry is the electronic voltage between 0-10 Volt signal and I need accuracy of 0.1 Volts. Is it possible to get a digital output on the computer (such as USB) and convert it into an analog signal within the corresponding range through the use of the products OR commercially available?

Best,

Sertan.

Hi Sertan,

If you are looking for a specific product range, it seems that our M-series products will provide your desired features: USB, +/-10V output analog and a higher accuracy you need. Nice day!

-

USB 6008 weird analog voltage reading

Hello

I use the USB-6008 to measure a voltage of a Lithium battery, 3.66V.

the battery come with a blocking diode (in series with the battery) of 1N5820, who have a fall of voltage drop of 0, 1V.

battery with diodes in series (this is the way in which the battery is shipped with)

-measure with DDM yield 3.66V without you connect to usb6008

-measure with DDM yield connected to usb6008 (putting OUT VOLTAGE USB6008) 3.59V

-able with USB-6008 performance 3.59V connected to usb6008

battery with diode removed

-measure with DDM yield 3.66V without you connect to usb6008

-measure with DDM yield connected to usb6008 (putting OUT VOLTAGE USB6008) 3.66V

-able with USB-6008 performance 3.66V connected to usb6008

Thus, it seems that the problem is in the led in the series. This is why the battery voltage has fallen to 0.07V? the series diode will hurt the USB-6008?

Maybe people who know the circuits inside the USB-6008 can give me an answer.

Thanks in advance.

Hi learnerd,.

The fall that you see is falling forward in the diode. As an entry class device, the USB-6008 case has a relatively low input impedance (144kOhm) and thus draws a little current of the device. Looking at the datasheet of the 1N5820 (http://www.onsemi.com/pub_link/Collateral/1N5820-D.PDF), Figure 7 shows that at 25 ° C, a draw of 50mA will cause a fall front of 200mV. While the figure does not extend the curve below 50mA, extrapolating the given curve would indicate that a drop of 70mV would cause only a few current microamperes.

A DMM will have a much greater input impedance (GOhms instead of kohm) and won't draw enough current to influence the measure, that's why you wouldn't see the decline with only the DMM.

The diode will not harm the USB-6008 somehow.

Good luck with your application,

The f

-

Sampling motion controller analog voltage (from a load cell)

Dear nstroud,

Or the other of these commissions should work for you. You can configure one of the axes for engines step by step closed loop analog feedback and then put in place the other 2 axes as slaves to the first with a debt ratio of 1 to 1. This would cause all 3 of your axes to behave in the exact same way. This transmission is made on the card, and you should not see any negative impact on the axes update rates. The specified sampling rate should not be a problem either. The update of control loop period is definable in the adjustment of the loop tab, and for stepper motor axes, it determines how ofter the step generator is updated. The default for this value is 250 milliseconds. The 7340 user manual also lists the scanning speed of demultiplexer of analog input @ channel 25 microseconds / activated.

So you would be actually sampling and update the engine generator step much faster than 100 Hz with analog feedback on axis controllers.

See this knowledge base for more information about the configuration:

Analog feedback with a stepper motor:

http://digital.NI.com/public.nsf/allkb/AB3CCA7FBFAD749A8625713B001D8581?OpenDocumentBest regards

~ Nate

Maybe you are looking for

-

Accessibility: why is there no shortcut for Page Info in Windows?

On Linux and Mac, there is a keyboard shortcut for Page Info:Linux: ctrl + IMac: cmd + Ibut there is no shortcut for Windows relatives, we are forced to use a mouse. An extension should not be required for basic accessibility features.

-

Hp2540: HP2540 while one claim Code

I installed my 2540 all-in-one just fine except for the Web print service. I tried the code of print request but in vain. The test page that he print not include it.I logged on the built-in Web server, but there is no Web Services option on the netwo

-

Error 8000FFF with KB98266 Vista

This security up to this day will not be installed. I ran the proposed automatic fix and tried the manual correction without result. Windows Update keeps telling me I have to install the update, but then it does not install.

-

ZBook 14: ZBook 14 wireless problem solved!

For a few months now, my ZBook 14 (still under warranty) drivers wireless (Intel Wireless - N 7260 BN) were not loading at startup about 50% of the time. Pilots would almost always successfully load if I restarted, but it was aggravating circumstanc

-

Hello world IM struggling a bit here and for once google was not all useful. I have a Win7 64 bit OS, where I have my jdk 64-bit installed for other projects, I'm working on that. I must now do some development work light and is one of the things tha