Pulse train generation question-PCIe-6320

Hi all...

IM using PCIe-6320 series daq x to generate trains of pulses. I went through the examples found in the labview to generate digital impulses. Provided vi runs without error, but I could not find any pulse output in my PIN ctr0. Is there a specific connection to check the output?

Hello..

I had a problem with the interface cable, I found this later.thanks.now I havesolved.

Tags: NI Hardware

Similar Questions

-

Counter/Timer Pulse Train generation

Hello

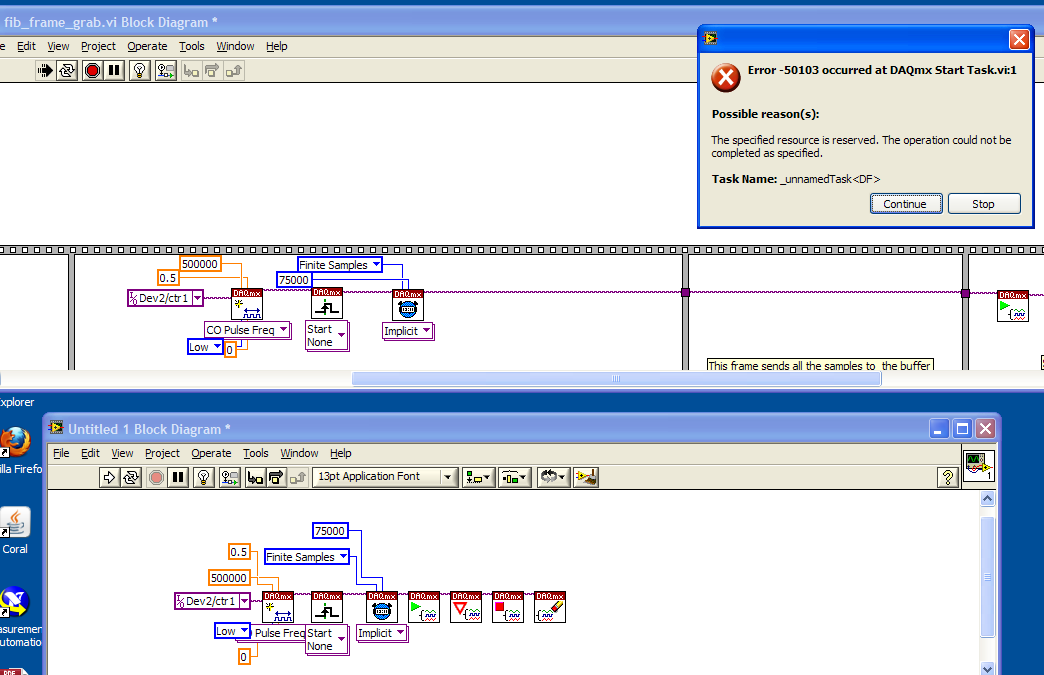

I'm having some difficulty to understand why a particular VI I does not work (upper part of the image below), I was wondering if someone could give me an idea of the cause of the error message. I have a counter/timer, which I use to generate a pulse train. It works very well on samples of "continuous", but when I turn it on to 'finished samples' I get an error of "resource is reserved" when it comes to the DAQmx VI of 'play '.

I made an another VI (lower part of the image) and it works very well with finished samples. So basically I wonder what's different on finishes versus continuous sampling which could cause a resource to book or not. (the Board of Directors is a PXI-6281 if it matters)

Thank you

Adam

OK, I just looked through the manual and it seems that when you do a finish on a counter pulse train generation, the jury must in fact to divert the OTHER counter.

This may have been aparent earlier if the error message about what resources he tried to get was more prolific.

In any case, problem solved I guess.

-

Generate a pulse trains finished redeclenchables 2 of different duration using 2 counters

Hello

What I want to do is to generate at the same time 2 redeclenchables finite pulse trains using my PCI-6221.

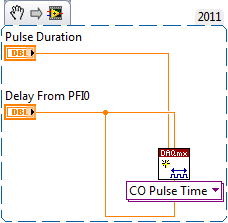

To be more clear, take a look at the attachment.

Relaxation is in/dev/PFI0 for example and I want 2 impulses/dev/ctr0 and/dev/ctr1 at the same time.

I can easily produce/dev/ctr0 or/dev/ctr1, but never/dev/ctr0 and/dev/ctr1 at the same time.

It sounds feasible that I want to achieve?

Thank you very much.

Adrian

I couldn't open your VI as I use LV 2011 on this desktop computer.

However, you must just on delay initial as well as the low time some delay desired with respsect to PFI0 on the ctr0 task.

Other NI DAQ products behave differently, but the 6221 uses "shortly" for the initial delay for each output reset after the first.

Best regards

-

Problem with the generation of two internal counters pulse trains

Hello

I do a control of temperature for two heaters, OR 9472 (output module digital), NI 9271 (RTD for measuring temperatures) and cDAQ-9174 chassis. So, I use the internal meter NI 9174 to generate two pulse train on the outputs (I tried with both cases-> pulse continuous and finite). Before that, I have two separate PID.vi, in which each sent the percentage of cycle of obligation for the two tasks of pulse generation (I configured these tasks with the physical channel cDAQ1Mod1/ctr0 and cDAQ1Mod1/ctr1). The problem is when I run the program, because the application initially worked fine, but after a few seconds the communication between the chassis and the application is not respected (no error message, but the external LEDs on the NI 9472 module had been disabled and stopped too NI 9271 module temperature readings). Then I tried to stop it with a 'Stop' button, but nothing happens. After, I abandoned the race and still nothing happened. So, I finished the Labview program with the Task Manager and a message appeared "reset VI: xxxxx". Finally, I have to restart my computer to run the program again. Can anyone help with this please? If you need more information, let me know.

Kind regards

Hi Luis,.

I have the error cluster connected. But I solved my problem in a different way. I don't know why, but when I configured my RTD module with the DAQ assistant to test some of my design in a new file in VI, the RTD module works fine, but if I copy the entire program logic (include my DAQ assistant) back to my main VI folder and run the application, only for communication between my DAQ hardware and my software works there shortly. So I solved my problem set up any device or module in the same file from the application again and problem disappears.

Thanks for your help.

Luis C.

-

No count output / pulse pulse does in a meter of pcie-6320

Hi all

IM using pcie-6320 in my application to generate impulses using the counter i/o.Even when I try to generate/counting pulses using MAX, I coundnt find no exit, im watching the e/s using a CRO. My camera works very well and tested hardware DAQ Diagnostic Utility tool in this tool also spent the meter test. IM completely stuck here, if anyone has come across such a problem please help me.

Hello.. I solved the problem. In fact, it was found that the cable between junction box and data acquisition is not properly inserted. In any case thanks for your contributions

-

I need to generate 3.3 V logic level Digital train of pulses with the NI PCI-6221. Can I change the level of 6221 OR logic output?

The output cannot be changed. 5V to 3, 3V level controllers are readily available (Maxim, I think). As long as the scanning speed (etc.) is fast enough for your pulse train, even 3, 3V regulator would work. I don't know if NEITHER offers a module to condition TTL levels.

-

Continued use of digital dashboard to stop a generation pulse train

Hello

I need to generate a train of pulses for a period of time. However, this period is variable, and because of that I can't

Use the finite number of samples.

The pulse train must be output depending on the State of the digital I/o. When the line output goes high, must be output of the pulse train.

and when he goes down the pulse train should be stopped.

I use a USB-6212, but is already using one of the available counters for the measurement of pulse width. I tried to do a

AND logic with the pulse train and line activate, but due to the execution time of vi this solution modifies the pulse train

frequency, which is not acceptable.

Thanks in advance,

Mariana.

Hi Marianne,.

Your previous message mentioned "line in/out" (in the singular) and "enable line" (in the singular), isn't "the i/o lines" (in the plural). Are the two edges on the same line in/out? Or are they on separate i/o lines (for example, climbing on PFI0, falling on PFI1)? Can you clarify your needs?

If the fronts and sides come from the same line of output, then a relaxing break seems to do what you want: cause the meter generate impulses while the input/output line is high and cause the meter to stop while the input/output line is low. However, if you start the job, while the input/output line is high, it will immediately start out impulses. If you want to wait the first front line input/output to generate impulses, you can use a trigger 'start of arms' (which is just below "break" in the node property). When the trigger 'arms beginning' arrives, the meter will be armed, and therefore, the task uses the break to determine when to generate impulses. Using pause and start the same counter task returns error-200146, "put in Pause and start triggers cannot be active in this task," but using break and triggers 'arms beginning' in the same task of counter should be correct.

If you want to increase the edges of PFI0 to start the meter and the fall of the edges of PFI1 to stop the meter, which is more complicated and it will take thought additional (and possibly additional hardware).

Brad

-

several finite pulse trains of TTL

Dear members of the forum OR,.

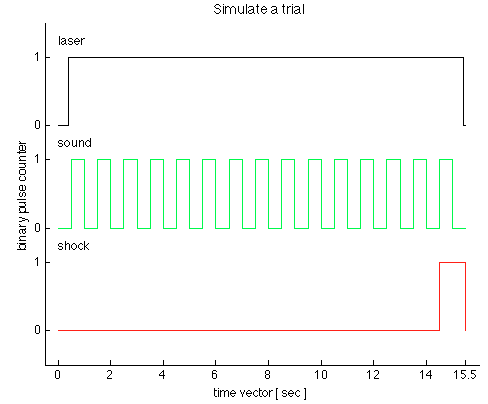

We have just received a chassis NI SMU-1073 with an SMU-6361 OR switched in PXI1Slot2 and a shielded connector BNC-2111. Aims to generate trains of three TTL pulses to control a laser, sound and shock via Matlab Application. I use the C OR-DAQmx API with Matlab MEX to integrate C in Matlab code.

I came up with the following code in the examples in C to generate a pulse over TTL time-based train:

initialDelay float64;

float64 lowTime;

float64 highTime;

uInt64 periodsPerTrain;

float64 taskMaxTime = (lowTime + highTime) * periodsPerTrain + 2 * initialDelay;Configure Pulse

DAQmxErrChk (DAQmxCreateTask ("", & taskHandle));

DAQmxErrChk (DAQmxCreateCOPulseChanTime (taskHandle, "PXI1Slot2/ctr0","", DAQmx_Val_Seconds, DAQmx_Val_Low, initialDelay, lowTime, highTime));Configure the Pulse Train

DAQmxErrChk (DAQmxCfgImplicitTiming (taskHandle, DAQmx_Val_FiniteSamps, periodsPerTrain));Departure Train

DAQmxErrChk (DAQmxStartTask (taskHandle));Wait for execution

DAQmxErrChk (DAQmxWaitUntilTaskDone (taskHandle, taskMaxTime));Clean

DAQmxStopTask (taskHandle);

DAQmxClearTask (taskHandle);I'm stuck with two problems:

1.) SMU-6361 has 4 meter signals ctr0-3. With the above code, I can generate separate tasks for each TTL signal and evoke them consecutively with DAQmxStartTask. But in this case, I guess that the tasks are not synchronized. Can I use the clock signal to synchronize the other 3, for the tasks of each is triggered at the same time? What will be the right way to do this with the C API? The step of the smallest of the discrete-time in the example is 500ms. see the picture as an attachment to check how the TTL signals should look like.

(2.) what is my physical connector on the BNC2111 to outsource these signals.

/ PXI1Slot2 / ctr0-> PFI12/P2.4

/ PXI1Slot2 / ctr1-> PFI13/P1.0

But what ctr2 and ctr3? How can I configure the physical connector outsource? Is there a function to specify that?

Thank you in advance for any advice, suggestions and directions!

see you soon,

go9kata

Hello go9kata,

for your second question, with the BNC-2111. You can route the signal from the counter for

lines PFI avialable on the block of connection BNC 2111 with the following syntax

DAQmxErrChk (DAQmxSetCOPulseTerm(taskHandle,"/Dev1/PFI0"));

I hope that helps, if not please let me know.

-

Create two independent signals and a pulse train with NI USB-6259

Hi all

I'm new to the forum, I searched but I've found no info about it.

I have recently set up a vi that is able to generate from an NI USB-6259 case two different signals in frequency, amplitude and phase (see attachment).

To do this with each cycle of the memory buffer size is changed accordingly for frequencies in order to see a whole number of periods and, thus, having not leak in the generation (or breaks).

Now, I would like to generate a pulse train at a frequency that is an integer multiple of the frequency of the input signal (not the 50 Hz one).

The resulting frequency of the pulse train could be changed on the fly (or at least be updated at each new round of vi).

I'm stuck because I have already said that two analog output channels and I want the pulse train so that a digital camera for my Board (channel PFI) output, you have any ideas?

Thank you very much

Alberto

PS. the vi is "program generazione.vi" but you must first install "signal.vi production".

Hello

It is a simple .vi which generates a configurable, buffered pulse train dynamically. I also want to let you know that with this type of advice (DAQ), it is impossible to update the output in real time. You must be careful because the time between you use "DAQmx Write" and the output effective physical change not IS NOT FIXED.Kind regards

Matteo

-

Redeclenchee HW with line Enable Pulse Train

I am using the 'Multi-multifunction-Ctr Retrigg Train generation of impulses for the Clock.vi sample' in the Finder for example LabVIEW to sample a waveform. It worked great, but now I need to sync my purchase with another piece of equipment. The material defines a "Enable" high TTL line when it is ready to acquire and I need to start my purchase at the pulse of available next synchronization. The option "Activate" is low and I have to stop acquiring after than the gust / the current image is complete. I tried to use a line of 'Pause' and a 'Digital Plan' trigger but doesn't seem to work with a finite pulse train. Since it kinda is diffficult to explain in the text, I have attached a waveform.

Any suggestions? I use an inLabVIEW DAQPad 6016 8.5.

I would treat differently the digital. If you watch the digital parallel and just read single points, then you will have a quick way to signal to the loop to HAVE the enable option has been low. I added an untested VI which should give you the idea. There is probably a better way to manage stopping both loops, I just did a quick and dirty method. After watching your VI it dawned on me that you could build a machine of the State where he's just looking for available samples then actually starts reading, and once there are no samples available after a certain period of time you would stop. You would still need the door AND but would not need to worry monitors the enable line. This would be probably as fast that monitors the line to activate it if.

For a door AND every door TTL AND must accept a 5 V power supply. If I remember just a 74LS08 should work - if you only need the one you may be able to get a free sample.

see you soon,

Andrew S

-

How to generate a variable frequency pulse train constantly

Hi all

I am using NOR-USB-6259 (BNC) to send signals of impulse to the position of a servo with labview motor control. The position of the servo-motor control follows these rules:

- The pulse train number determines how many degrees the motor;(par exemple la position angulaire dele de moteur)

- The pulse frequency determines how fast the engine is running; (for example the engine rotation speed)

- Digital determines the direction of rotation of the engine (for example in the clockwise or counterclockwise)

My question is when I have to continuously generate a body finished, train signal in a period of time. Here's a sample:

Time (s)

Number of pulses

Direction of rotation

(1 clockwise, counterclockwise 0)

Frequency

0-1

923

1

923hz

1-2

3540

0

3540hz

2-3

1751

1

1751hz

3-4

2663

0

2663hz

4-5

353

0

353hz

5-6

1017

1

1017hz

6-7

3436

1

3436hz

7-8

10 p

0

302hz

8-9

1513

1

1513hz

9-10

570

1

570hz

Here is the explanation of this table, the motor continues to turn clockwise for 0 ~ 1s. When the time reaches 1 s, the engine simply fill out the rotation of 923 pulse signals. And then the engine starts to turn clockwise for 1 sec ~ 2 s. When the time reaches 2 s, the engine simply fill out the rotation of 3540 pulse signals. So we can see that the speed of rotation of the motor to 0 ~ 1 s is different from the speed in 1 ~ 2 s. Namely, the frequency of the signal from pulse to 0 ~ 1 s is different from the frequency in 1 ~ 2 s.

I already use the DAQmx counter output, it can simply generate pulse signal with some numbers and some frequency only once. The attachment is the vi that allows to generate a digital pulse train finished the meter output channel and frequency, cyclical, delay report Initial and idle state are all configurable.

How can I continuously generate a series of pulse train with a variable number and frequency for a certain period of time.

Thank you very much for your help!

The frequency 'on the fly' control requires intervention of software and can not guarantee a specific number of impulses for each rate (which I assume you want because it's an engine step by step).

If it was me I would do one of them instead:

1. use the digital output for everything. The digital output at a higher clock rate and build the waveform to give you the desired number of steps and management. This method would give less temporal resolution than others.

2. use a task of meter output, 1 section at a time. Reconfigure and restart the task for each section after the management output setting. This method could introduce a delay between each section.

3. purchase of new equipment - X series supports put buffered outputs of meter that can do what you ask.

Best regards

-

How do you create a pulse train finished using a FP-CTR-502?

Recently, I replaced my FP-PG-522 module with a module FP-CTR-502, to achieve higher output frequencies (FP-PG-522 freq to maximum output is 5 kHz, while the FP-CTR-502 output max freq is 16 kHz).

I need to be able to generate a pulse train finished. Has anyone created a pulse train finished using a FP-CTR-502 module front? I started to study the issue, but my ideas so far have been complicated (compared to doing it in a PG module).

Advice on this would be much appreciated.

I can answer this question myself!

The answer is in the * OLD * version (July 2000) the operator of the manual for the FP-CTR-502. For some reason, it has been removed from the version the most recent (June 2003).

See page 11 of this link for more information:

http://www.NI.com/PDF/manuals/322660a.PDF -

Generate a pulse train, NI 9402 modules in cDAQ-9174 chassis

I have two modules NI 9402 in a cDAQ-9174 chassis.

When I output a pulse train on a specific line of the PFI to a specific module, the pulse train is out on the right line of PFI, but on BOTH modules.

I want that the pulse train out only one of the modules.

for example, I select cDAQ2Mod1/ctr1 to output a pulse train on PFI3 of module one. I hear the pulse module one PFI3 train, but I also get it on PFI3 of module 2.

I am also a measurement of separation of two edges with a different counter, but I don't seem to have this problem. (The measure only works when I have the signals connected to the module that I've specified.)

-Paul

This is the Vi I work with.

Hmmm... Looks like it's actually only after I exit a signal on that line. Maybe I should try to clear the line.

-Paul

-

I'm putting in place the PCIe-6320 with two rotary encoders for measuring position.

I wired to the top of my encoder (double quadrature with A, B, Z, V + and Gnd son) to my DAQ PCIe-6320 through a block of connection SCB-68. I used the source of external power supply for the encoder so all I am connected, it was channels A, B and Z I checked my wiring. Counter 0 uses 37, 45 and 3 pins.

When I connect it, there are a few problems: measurement and Automation Explorer (MAX), I go to the counter function test and it does not register. Using a multimeter, when the encoder is not connected I get some sort of output of three strings. But once I connect it to data acquisition, I get nothing.

The works of automatic test in the MAX software and calibration seems to go successfully.

What could be the problem here? Is it possible that data acquisition is broken, even if it passes the self test?

I think I know what is happening. The outputs are open collector, then you may need to pull up resistors. See page 9 (page 7 in characters) in the pdf file:

http://www.ctiautomation.NET/PDF/ACCU-coder/ACCU-coder-installation-wiring-Guide.PDF

Since you are using an external power supply, instead of the end of the resistance of your + VCC (6 volts in your case) you will need to connect it to the output + 5 which is probably available on your data acquisition card. This will ensure that the output does not exceed levels TTL (5V). You then bind the town or the mass of your power of 6V to digital DRM to your data acquisition card.

DAQmx are pilots and vi for the material. If you have MAX, you can check presence and version of data acquisition in the software listing in MAX.

I hope this helps.

-AK2DM

-

How to connect to the list of the pins for a redeclenchables pulse train

Hello

I'm relatively new toDAQmx, especially for the counters. I have problems to determine what pins to plug on the DAQ card. I would like to run the vi described here, but am not sure how to connect the card. I looked at the manual of the X series for the pinout descriptions, but I don't know how they apply to the program on this page. When I connect DOOR a meter, THE, A, B pins, etc.?

Any input on what to connect or pages that may make how to connect the counters would be very useful.

Thank you.

Your most recent post of links to an example more advanced sounding & I recommend that stick you with something simple to start.

Your first post links to such an an example where the signal of pulse train going out of Ctr0_Out. Ctr1 is used to make the trigger and the 'break' (enable / disable) Ctr0. However, much of this stuff is configured using some features of DAQmx such that you don't need to physically connect the pins between the two counters.

Only physical wiring that you need is to plug your physical digital trigger to the PFI1 signal and connect Ctr0_Out to some external thing must receive them. As long as your device is called "Dev1", I think this example to work.

I know there are some docs useful for more general info on the pins meter & behavior, but I don't remember quite so that I have not watched for them for many years. Meanwhile, here is a * little * bit General description I wrote myself once.

-Kevin P

Maybe you are looking for

-

Satellite L50-B-2E2 - keyboard backlight does not work

Hi guys. I have a big problem on my laptop with my backlight, so I have a Satellite L50 - B and the backlight, it does not. I tried Fn + Z but nothing... If someone knows how, please help me.

-

When ik mijn laptop opstart is steeds mijn printer verdwenen en moet ik hem terug installeren openen. Het gaat on officejet Hp 6600. Through the probleemoplosser kan ik het oplossen omdat hij printer niet dan niet vind ik hem terug installeer when en

-

I have a Canon AE1 progra. What I use for this suit a new EOS Reber T3I?

The goal of camer Canon AE1 Program fit the EOS or EOS Rebel T3I cameras?

-

Why not a movie made Windows Movie Maker - do NOT play on some DVD players? What can I do for the DVD player to allow the DVD to play?

-

Microsoft LIFECAM-VX 5500 Help! Since the update "-Audio and Microsoft, Communication device, Streaming Media Broadcast - Microsoft LifeCam VX-5500" it has not worked. The program does not open and when I try it says "stopped working". Also, when in